An impact wrench is a powerful tool predominantly employed in automotive and industrial settings, renowned for its capability to deliver high torque output with minimal effort from the user. Unlike traditional wrenches that rely solely on manual force, impact wrenches utilize a rotational hammering mechanism to apply massive torque, thus facilitating the loosening and fastening of nuts and bolts much more efficiently. This tool is particularly useful in situations where tight or stubborn fasteners need to be addressed, such as in vehicle maintenance or assembly line production.

The operation of an impact wrench operates on a simple yet effective principle. When the user engages the tool, it generates a series of intense bursts of rotational force, effectively breaking the grip of rusted or overtightened fasteners. The device achieves this through an internal hammer and anvil system; as the motor spins the anvil, the hammer spins and then strikes the anvil, producing a sudden increase in torque. This mechanism allows impact wrenches to exceed the torque output of standard hand tools significantly.

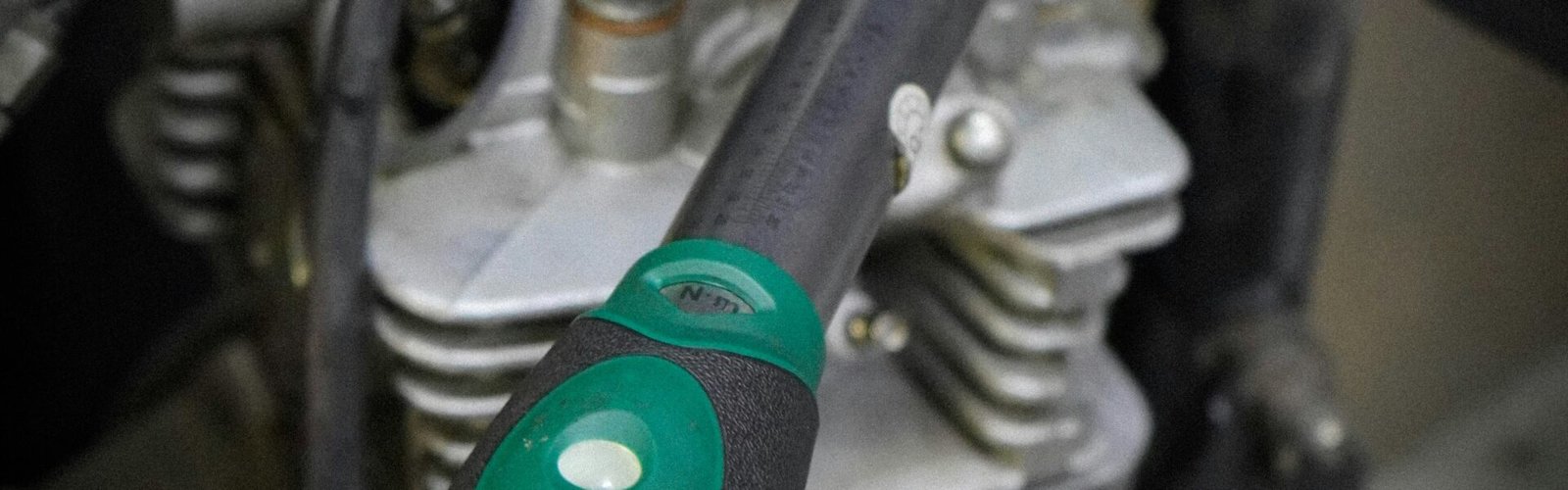

Impact wrenches can be categorized into two primary types: pneumatic and electric. Pneumatic wrenches rely on compressed air, making them common in professional garages and workshops, while electric models offer greater portability, perfect for home users and those working in areas without air supply. Moreover, their significance extends beyond automotive tasks; they find utility in various construction applications, including assembly, disassembly, and maintenance of heavy machinery. Thus, the impact wrench stands as a crucial component of modern toolkits, merging efficiency and power to improve productivity across diverse fields.

Types of Impact Wrenches

Impact wrenches are essential tools widely used in various industries, each type characterized by its power source and specific applications. The three predominant types of impact wrenches available on the market are pneumatic (air-powered), electric corded, and battery-powered (cordless) wrenches. Understanding the pros and cons of each type can help users select the most suitable option for their needs.

Pneumatic impact wrenches utilize compressed air to deliver high torque output. They are typically lighter and more powerful than their electric counterparts, making them favored in industrial settings such as automotive repair and construction. However, they require an air compressor, which may limit their portability and convenience for mobile use. Additionally, air-powered wrenches can be noisy and may necessitate the use of ear protection.

Electric corded impact wrenches, on the other hand, plug into a standard power outlet, providing consistent power without the need for an air compressor. They are generally heavier than pneumatic models but often offer a good balance between power and convenience. Such wrenches are suitable for both home and professional use, excelling in tasks that require continuous operation without interruption. However, their reliance on a power source can hinder mobility, making them less ideal for outdoor applications.

Battery-powered or cordless impact wrenches have surged in popularity due to their portability and ease of use. These wrenches are equipped with rechargeable batteries, allowing users to work anywhere without being tethered to a power outlet. They are perfect for tasks requiring versatility, such as automotive maintenance and household repairs. Nonetheless, battery life and charge time can be limiting factors, especially for heavy-duty applications, so selecting an adequately powered battery is crucial.

Applications in Automotive Maintenance

Impact wrenches are indispensable tools in the realm of automotive maintenance, offering essential functions that significantly enhance both efficiency and effectiveness in various tasks. One of the primary applications of an impact wrench is the removal of lug nuts. Traditionally, this task required substantial physical effort, often leading to strain or injury. However, with the use of an impact wrench, technicians can swiftly and effortlessly loosen lug nuts, making tire changes more manageable for both professionals and DIY enthusiasts.

In addition to lug nut removal, impact wrenches are highly effective for tightening bolts. This function is crucial in various automotive repairs, where achieving the correct torque is vital for safety and reliability. An impact wrench delivers high torque output, allowing users to tighten bolts quickly and to the manufacturer’s specifications, thereby reducing the risk of over-tightening or damaging components.

Furthermore, regular service checks are simplified with the incorporation of an impact wrench into maintenance routines. Tasks such as changing brake pads, replacing exhaust systems, and performing engine work can benefit greatly from the speed and power that impact wrenches afford. They can help streamline workflows, enabling technicians to complete jobs in a fraction of the time it would take with manual tools.

Ultimately, the advantages of using an impact wrench extend beyond time savings. For professionals, it can lead to increased productivity and reduced labor costs, while for DIY enthusiasts, it can enhance the overall vehicle maintenance experience, making complex tasks more approachable. Given the significant impact that an impact wrench can have in automotive maintenance, it stands out as a must-have tool for those engaged in both professional and home-based auto repair activities.

Impact Wrench Uses in Construction

Impact wrenches have become indispensable tools in the construction industry due to their efficiency in handling various fastening tasks. These power tools are specifically designed to deliver high torque output, making them ideal for the assembly and disassembly of structural elements. In construction, where precision and speed are paramount, the ability of an impact wrench to quickly tighten or loosen fasteners is crucial.

One of the most prevalent applications of impact wrenches in construction is the fastening of heavy-duty materials. For instance, during the erection of steel frameworks, workers often use impact wrenches to secure bolts in place with precision. This not only reduces the time taken to complete the assembly but also ensures that the structural integrity is maintained throughout the process. In scenarios where multiple bolts need to be fastened rapidly, the impact wrench significantly outperforms manual tools.

Additionally, impact wrenches contribute to speeding up the overall construction process. For example, in residential building projects, contractors utilize impact wrenches to quickly attach roof trusses or install heavy machinery. The time saved in fastening components translates into increased efficiency, allowing projects to meet deadlines more effectively. Furthermore, with advancements in battery technology, cordless impact wrenches are gaining popularity on construction sites, providing mobility without sacrificing power or performance.

Moreover, the versatility of impact wrenches extends to assembly lines within the construction industry. They are commonly employed in prefabrication facilities to assemble components before transporting them to the job site. This method enhances productivity, as elements can be pre-assembled rapidly, minimizing on-site labor. As construction techniques evolve, the impact wrench’s role continues to expand, affirming its value as a critical tool in modern construction practices.

Benefits over Traditional Tools

The advent of the impact wrench represents a significant technological advancement in the realm of hand tools and power tools. Unlike traditional hand tools, which rely on human strength and effort to apply torque, impact wrenches utilize a unique mechanism that allows for greater torque delivery with minimal user input. This feature is particularly beneficial when working with stubborn or rusted bolts, where traditional tools may struggle to achieve the necessary force. As a result, tasks that would typically require considerable physical effort are accomplished with ease, thereby reducing the risk of strain or injury.

Moreover, impact wrenches are designed to deliver rapid bursts of rotational force that substantially increase the speed of fastening tasks. While hand tools such as wrenches can be time-consuming and labor-intensive, impact wrenches enable users to complete jobs more quickly and efficiently. This heightened speed is especially advantageous in professional settings, such as automotive repair, construction, and assembly lines, where time is often of the essence. Workers can move from one task to the next without cumbersome interruptions, thus enhancing overall productivity.

Another significant advantage of impact wrenches over both traditional tools and other power tools is their versatility. Many models come with different drive sizes and attachments, allowing users to tackle a wide array of fastening tasks across various applications. This modularity often negates the need to invest in multiple tools, contributing to cost-effectiveness. Furthermore, the reduced physical effort required to operate an impact wrench means that users can maintain stamina over prolonged periods of work, enhancing comfort and efficiency. Ultimately, the transition from traditional tools to impact wrenches offers numerous benefits that translate into enhanced performance and user safety.

Selecting the Right Impact Wrench for Your Needs

Choosing the right impact wrench is a crucial step that can significantly enhance your efficiency in various tasks, whether in automotive repair, construction, or general maintenance. To make an informed decision, several key factors must be considered, including torque ratings, size, weight, and additional features that could be advantageous for your specific applications.

Torque ratings are among the most important specifications when selecting an impact wrench. They determine the tool’s ability to loosen or tighten fasteners effectively. For tasks involving heavy-duty applications, consider tools with higher torque ratings, typically measured in foot-pounds (ft-lb) or Newton-meters (Nm). It’s essential to assess the type of projects you plan to undertake; for lighter jobs, a lower torque rating may suffice, while more substantial tasks warrant a high-performance impact wrench.

Size and weight also play significant roles in your selection process. A lightweight, compact model can enhance maneuverability, making it easier to access tight spaces. Conversely, a heavier model may offer increased durability and stability for extended use. Balancing these factors according to your comfort and the nature of your projects is key.

Additionally, consider the features offered by various models. Cordless impact wrenches provide the advantage of portability but require consideration of battery life and charging times. Conversely, corded models offer consistent power but may limit mobility. Some tools come with variable speed settings, which can enhance control during application. A built-in LED light can also be a useful feature, improving visibility in dimly lit areas.

Ultimately, assessing your frequency of use and setting a realistic budget are crucial steps in this process. By considering these factors, you can confidently select an impact wrench that meets your specific needs, ensuring effective and efficient performance in your tasks.

Maintenance Tips for Longevity

To ensure the longevity and optimal performance of an impact wrench, regular maintenance is essential. One of the primary aspects of this maintenance routine involves lubrication. Periodically applying the manufacturer-recommended lubricant to the tool’s moving parts helps reduce friction, ensuring smooth operation. It is advisable to consult the owner’s manual for specific lubrication points and intervals as this can vary among different models.

Cleaning the impact wrench is another crucial aspect of maintenance. After each use, it is beneficial to wipe down the tool to remove dust, debris, and any residues that may have accumulated during operation. For deeper cleaning, disassemble the wrench according to the manufacturer’s instructions and use compressed air to blow out any grit or particles, especially in the motor housing and air inlet. Ensuring that these areas are kept clean will help maintain air flow and prevent overheating.

Furthermore, checking for wear and tear is vital in preserving the integrity of the impact wrench. Inspect the anvil, trigger, and housing for cracks or damages regularly. If any parts show significant signs of wear, they should be replaced promptly to avoid further damage to the tool. It’s also a good practice to periodically test the performance of the wrench; for instance, checking if it produces the expected torque can indicate whether the tool is functioning correctly.

Lastly, proper storage cannot be overlooked. When not in use, store the impact wrench in a dry and cool place, preferably in a protective case. Avoid leaving it in damp environments, as moisture can lead to rust and electrical damage. Implementing these maintenance tips not only extends the life of your impact wrench but also ensures it continues to deliver reliable performance over years of use.

Safety Measures When Using Impact Wrenches

The use of impact wrenches offers considerable efficiency in various applications, yet it is essential to prioritize safety to ensure a secure working environment. Personal protective equipment (PPE) plays a crucial role in safeguarding the operator against potential hazards. To begin with, users should always wear safety goggles to protect their eyes from flying debris or potential tool malfunctions. Additionally, gloves made from durable, cut-resistant materials should be worn to minimize the risk of injury when handling tools or fastening components. Hearing protection is also recommended due to the high noise levels that impact wrenches can produce during operation.

Proper tool handling techniques are vital for ensuring safe operation of impact wrenches. Operators should familiarize themselves with the specific tool they are using, ensuring they understand its functionality and limitations. It is essential to maintain a firm grip on the tool and to position oneself appropriately to avoid any slips that could lead to accidents. Proper body posture is critical; Users should stand in a stable position with feet shoulder-width apart and keep hands clear from the rotating parts during operation. Furthermore, the torque settings should be appropriate for the job at hand, as using excessive force can lead to tool failure or accidental injury.

Awareness of surroundings cannot be overstated when operating power tools like impact wrenches. Users should ensure that their working area is free from any obstructions or hazards that could pose a risk. Furthermore, it is important to be mindful of others in the vicinity, as they can provide unexpected distractions or unwanted interference. By adopting these safety measures, including the use of appropriate PPE, adhering to proper handling techniques, and maintaining awareness, users can significantly reduce the likelihood of accidents and enhance their overall safety when using impact wrenches.

Conclusion: The Versatility of Impact Wrenches

In summary, impact wrenches have established themselves as indispensable tools across various industries due to their remarkable versatility and efficiency. These powerful tools are designed to deliver high torque output with minimal effort, which significantly reduces the time and energy required for repetitive tasks such as automotive repairs, construction, and assembly processes. Their ability to tackle stubborn fasteners and provide consistent performance has made them a favored choice among both professionals and DIY enthusiasts.

One of the primary benefits of impact wrenches is their efficiency in speeding up often labor-intensive mechanical tasks. For instance, in the automotive industry, mechanics frequently rely on impact wrenches to loosen or tighten lug nuts quickly during tire changes. This swift capability ensures that service times are minimized, ultimately improving customer satisfaction. Similarly, in construction and woodworking, these tools can effortlessly drive screws and bolts into tough materials, enhancing productivity on job sites.

The adaptability of impact wrenches is further evident in their compatibility with various attachments and accessories, allowing users to tackle a wide range of applications. From impact sockets to adaptor kits, users can customize their impact wrench setup to meet specific requirements, making them suitable for both light and heavy-duty tasks.

Overall, the importance of incorporating an impact wrench into one’s toolset cannot be overstated. Whether used in automotive work, home improvement, or industrial applications, these tools provide unparalleled power and ease of use. As technology continues to advance, the range of impact wrenches available will only expand, further enhancing their applications and reinforcing their status as a go-to tool for efficiency and effectiveness in mechanical tasks.